Automation in the bicycle workshop saves time

In the face of rapid technological advancements, automation is gaining importance across various sectors of the economy, and the bicycle industry is no exception. The introduction of innovative automation solutions into bicycle workshops opens up entirely new possibilities, translating into significant savings in both time and financial aspects.

Thanks to automation, processes in workshops become smoother and more efficient. For example, automated diagnostic systems allow for quicker identification of technical issues, significantly reducing repair times. Customers can enjoy faster service, while workshops gain in efficiency, ultimately leading to increased profits.

Another aspect worth highlighting is the precision offered by modern technologies. Automated machines for assembling and disassembling bicycle components eliminate the risk of human error, which not only improves the quality of services but also reduces losses associated with the need for corrections. In the long run, this translates into lower operational costs, benefiting both workshop owners and customers.

Automation in bicycle workshops also enables better inventory management. The use of integrated IT systems allows for real-time tracking of parts and accessories, minimizing the risk of downtime caused by a lack of necessary components. This allows workshops to focus on developing and refining their services.

In summary, automation in bicycle workshops is not just a trend but a necessity in today's competitive environment. The introduction of modern technologies not only enhances process efficiency but also impacts customer service quality and overall financial gains. Investing in automation is a step toward the future, bringing tangible benefits for both workshops and their customers.

In recent years, the bicycle industry has become an arena of intense innovation, with automation at the forefront of this transformation. The use of advanced automation technologies significantly improves efficiency and the quality of production processes, which is crucial in the face of growing demand for high-quality and diverse bicycles.

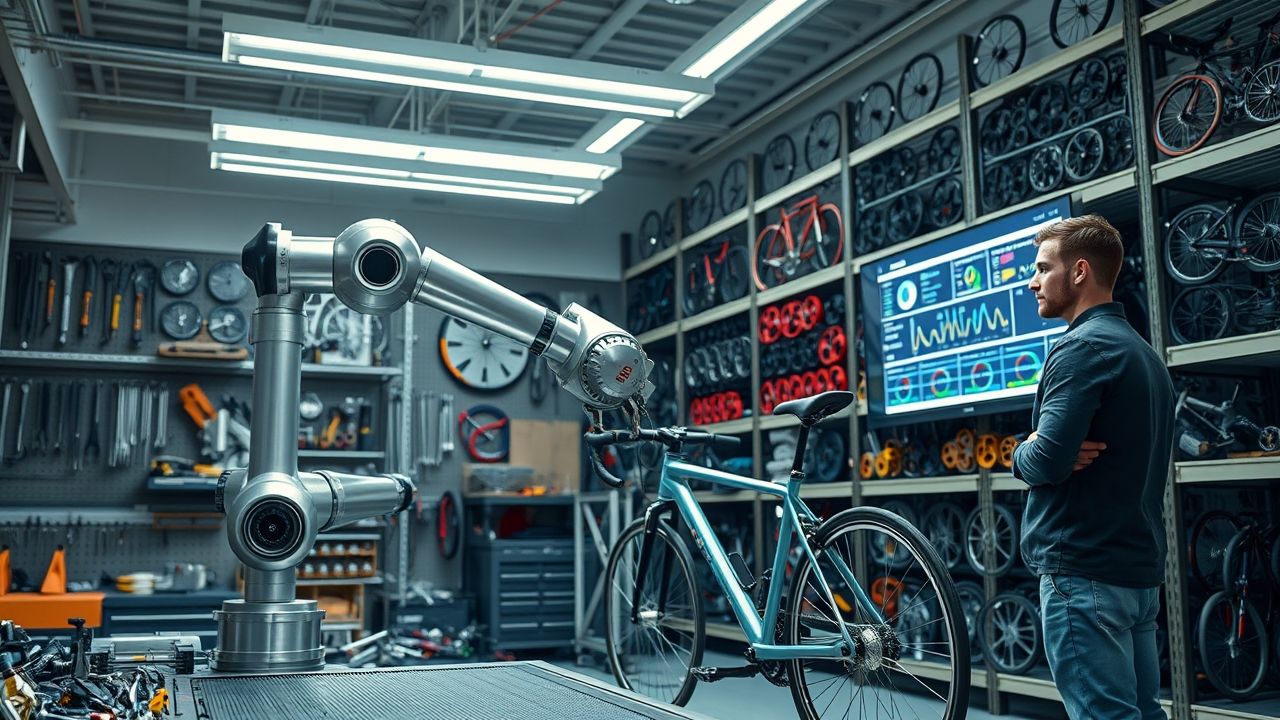

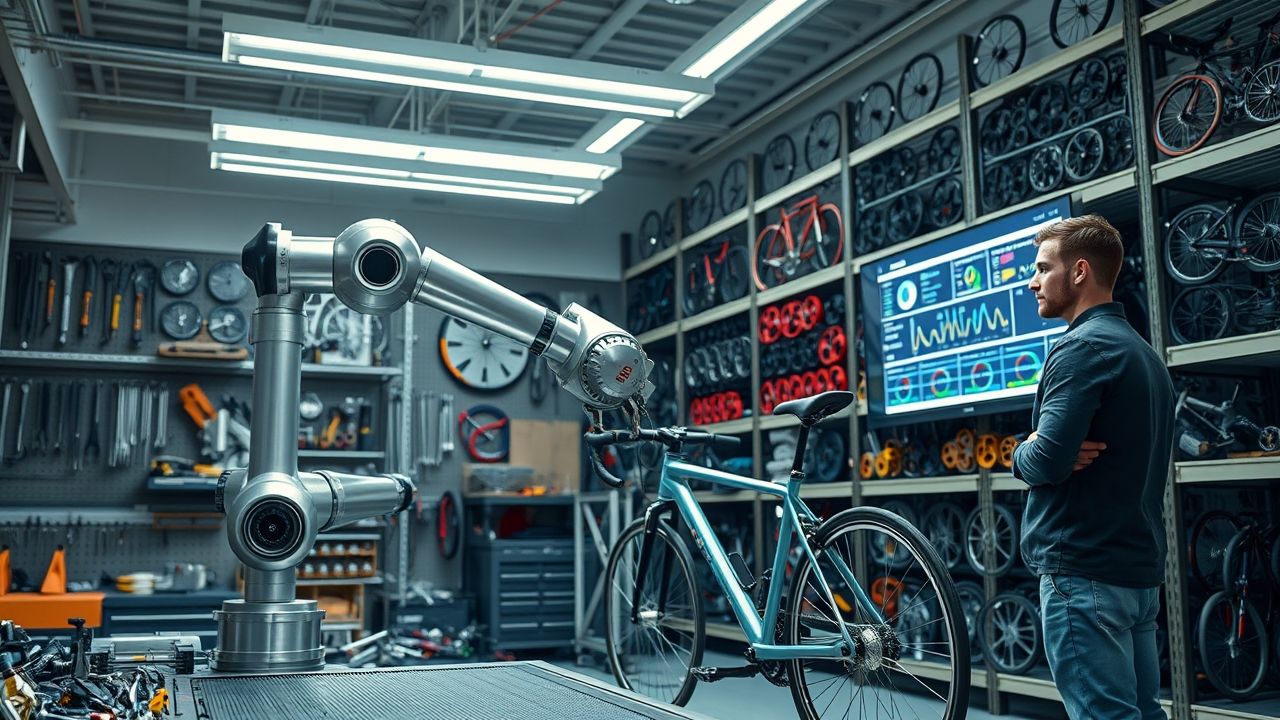

By implementing industrial robots, bicycle manufacturers can automate routine tasks such as assembly, painting, and quality control. These robots, equipped with precise tools and advanced algorithms, can work with unprecedented accuracy, leading to a significant increase in production efficiency. Additionally, their ability to work in challenging conditions and minimize human errors significantly enhances the quality of the final products.

Internet of Things (IoT) solutions also play a key role in automating processes in the bicycle industry. Thanks to smart sensors and network-connected devices, workshops can monitor inventory levels in real-time, analyze production data, and optimize processes on the fly. This kind of intelligent management allows for better market demand forecasting and faster responses to changing trends, thereby increasing the competitiveness of companies.

Moreover, sensor-based automation enables more precise manufacturing of bicycle components, directly impacting product quality and durability. The use of technologies such as vision analysis and force and torque sensors allows for defect detection during production, significantly reducing material waste and lowering production costs.

In summary, automation technologies in the bicycle industry not only increase efficiency and precision in production processes but also introduce a new quality to the entire production cycle. In the face of dynamic market changes, investments in automation have become an essential step for companies aiming to succeed in this competitive industry.

Today, automation is not just a trend but a necessity in many industries, and one of its most significant advantages is the substantial improvement in quality control and task repetition. Automated systems, thanks to their ability to conduct continuous and systematic quality checks, significantly reduce the workload on employees. Reducing pressure on staff not only boosts team morale but also minimizes the risk of human errors, which can be extremely costly and damaging to a company's reputation.

By implementing advanced technologies such as artificial intelligence and machine learning, automation systems can detect product irregularities in real-time. This enables immediate response and correction, making the production process more reliable and efficient. As a result, customers can enjoy higher-quality products, which in the long term builds brand trust and increases consumer loyalty.

Automation not only raises quality standards but also contributes to the optimization of production processes, leading to cost savings. In an era of growing competition and constant market changes, investing in automation has become a crucial step toward ensuring a lasting competitive advantage. In conclusion, quality control and task repetition, supported by automation, are the foundations upon which any enterprise aiming for excellence in its industry can build success.

Implementing the right workshop management software is a key step toward optimizing operational processes and increasing a company's competitiveness. Such IT solutions enable precise logistics tracking, which not only improves efficiency but also minimizes the risk of operational bottlenecks that can negatively impact workflow.

Advanced features such as inventory tracking, sales updates, and employee performance monitoring form the foundation of effective resource management. These tools allow managers to analyze inventory levels in real-time, optimizing purchasing processes and minimizing costs associated with excess stock. Additionally, real-time sales updates enable quick responses to market changes and better forecasting of future customer needs.

Monitoring employee performance is another aspect that significantly impacts workshop efficiency. The software allows for the collection of data on working hours, task completion, and service quality, enabling the identification of areas for improvement and motivating the team through goal-setting and recognition of achievements.

As a result, the use of modern workshop management software not only increases operational efficiency but also contributes to building a stronger market position by better meeting customer needs and effectively managing human resources. In today's rapidly changing business environment, investing in such solutions is not only beneficial but essential for the long-term success of any enterprise.

Modern production is becoming increasingly advanced through the integration of automated robotic systems, revolutionizing traditional manufacturing methods. Robotics is applied in various processes such as painting, assembly, and bicycle packaging, significantly increasing operational efficiency.

Robots, thanks to their precision and repeatability, contribute to a substantial improvement in product structural integrity. In the painting process, for example, robots ensure uniform coverage and minimize the risk of human errors, resulting in higher finish quality. In assembly, automation allows for faster and more accurate component joining, which is crucial in bicycle production, where every part must be perfectly fitted to ensure functionality and safety.

Additionally, the implementation of robotic systems reduces the need for manual labor, lowering production costs and allowing human resources to focus on more creative and strategic tasks. Savings from automation can effectively offset potential reliance on cheap labor and increase production flexibility, enabling quicker adaptation to changing market needs.

As a result, the use of robotics in production not only raises quality standards but also enhances the competitiveness of enterprises. In an era of rapid technological changes, investing in robotics is not only beneficial but essential for companies aiming to maintain a leading position in the industry.

In an era of dynamic market changes, automation has become a key element of operational strategies for many enterprises. Simplifying numerous production and administrative processes not only significantly reduces error rates but also increases organizational flexibility in the face of sudden changes, such as tariff regulations or labor cost fluctuations.

Focusing on tailored automation in the context of bicycle workshops opens new possibilities for product personalization. Thanks to innovative technologies, such workshops can efficiently and swiftly produce bicycles that meet unique customer requirements and preferences. Automating design and production processes not only speeds up order fulfillment but also allows for flexible adaptation to changing market tastes and expectations.

As a result, bicycle workshops that invest in personalized automation can not only increase their competitiveness but also build customer loyalty by offering products that fully meet individual needs. This approach creates an agile work environment that fosters innovation and continuous improvement, enabling companies not only to survive but to thrive in a complex and ever-changing business world.

In summary, automation in bicycle workshops opens up a wide range of benefits for entrepreneurs, translating into significant time and cost savings while also enhancing service quality. In today's rapidly evolving market, automation technologies have become a key element of development strategies, improving operational efficiency and production process quality.

By implementing modern robotics, bicycle workshops can perform tasks that previously required significant human effort, enabling faster and more precise service delivery. Production management software, on the other hand, allows for better inventory monitoring and process optimization, increasing customer satisfaction by reducing wait times for order completion.

The flexibility in production offered by modern technologies allows workshops to quickly adapt to changing market needs and individual customer expectations. This level of adaptability makes bicycle workshops more competitive, enabling them to effectively respond to growing consumer demands. Given all these advantages, automation is no longer just an option but a necessity for any modern workshop aiming to maintain a leading position in the bicycle industry.